What is Tensioning?

Processing Re-write Suggestions Done (Unique Article) Tensioning is that the direct axial stretching of the bolt to attain preload. Inaccuracies created through friction square measure eliminated. Massive mechanical effort to form torque is replaced with straight forward hydraulic pressure. the same load

can be applied by tensioning multiple studs at the same time.

Tensioning needs longer bolts, and a seats on the assembly around the nut. Tensioning will be done victimisation clastic Bolt Tensioners or Hydraulic buggy.

There are 3 way to Tension:-

1.Heat

2.Hydraulic Tensioners

3.Mechanical Tensioners

1. Tensioning with Heat:-

Gas Bolt Heater:-

Objective:-

Correctly setup a gas bolt heater

Properly adjust oxy-acetylene flame

Correctly adjust air flow

Safely operate a gas bolt heater

Design:-

Heating causes a bolt to grow in length

Relieves tension on the bolt

Gas Bolt Heater is machined from solid Stainless Steel

A single-bolt heater can be adapted to fit most bolt sizes by changing the heating tube diameter and length

Heater

Gas Bolt Heater

Processing Re-write Suggestions Done (Unique Article) Tensioning is that the direct axial stretching of the bolt to attain preload. Inaccuracies created through friction square measure eliminated. Massive mechanical effort to form torque is replaced with straight forward hydraulic pressure. the same load

can be applied by tensioning multiple studs at the same time.

Tensioning needs longer bolts, and a seats on the assembly around the nut. Tensioning will be done victimisation clastic Bolt Tensioners or Hydraulic buggy.

There are 3 way to Tension:-

1.Heat

2.Hydraulic Tensioners

3.Mechanical Tensioners

1. Tensioning with Heat:-

Gas Bolt Heater:-

Objective:-

Correctly setup a gas bolt heater

Properly adjust oxy-acetylene flame

Correctly adjust air flow

Safely operate a gas bolt heater

Design:-

Heating causes a bolt to grow in length

Relieves tension on the bolt

Gas Bolt Heater is machined from solid Stainless Steel

A single-bolt heater can be adapted to fit most bolt sizes by changing the heating tube diameter and length

Operation:-

Select a heating tube that is 1/8” smaller than the hole in the bolt and approximately 3” shorter than the depth of the hole

Install heating tube in bolt heater

Use stainless steel reducing bushing for smaller heating tubes

Use high-temperature thread compound

Tighten hand tight

Connect air line to bolt heater

Air pressure should be between 50-100 PSI

Set oxygen pressure to 14 PSI

Set Acetylene pressure to 7 PSI

Use Victor #5-W gas welding tip

Always use check valves

Adjust the flame to obtain a carburizing flame

Carburizing flame has an acetylene feather

Insert bolt heater into the bolt

Purge bolt cavity with air

Turn the air valve off

Insert welding tip into gas bolt heater

Gradually open the air valve approximately 1/8 turn

Observe the color of the heating tube through vent holes in the gas bolt heater

Maintain a cherry red color by adjusting the air valve

More air is cooler

Less air is hotter

For proper operation, a balance of pressure must be maintained between the welding tip and heating chamber back pressure

Excess back pressure will result in welding tip back-fire

If a back-fire occurs, close the acetylene valve, remove the welding tip from the bolt heater, purge the bolt cavity with air, and restart the heating process

PRO’S:

Minimum Muscle

CON’S:

Hot

Slow

Inaccurate

Hard on Studs

Must have hole

Rough on gaskets

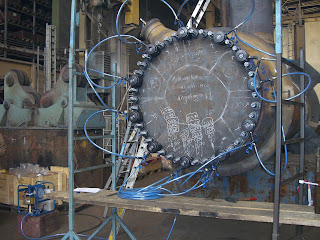

2. Hydraulic Tensioners

Various type of Hydraulic Tensioners

1.Top Connect

2.Side Connect

3.Hydraulic Nut

Top Connect Side Connect Hydraulic Nut

3.Mechanical Tensioner:-

-Multiple Work

-Takes Forever

-Tiny Load Points

-Cant check Results

SIONERS

HYDRAULIC

VARIOUS TYPE OF HYDRAULIC TENSIONERS

Gas Bolt Heater